Laser and Vehicle Manufacturing Technologies

Team leader: Krisztián Bán, PhD

The main professional and research areas

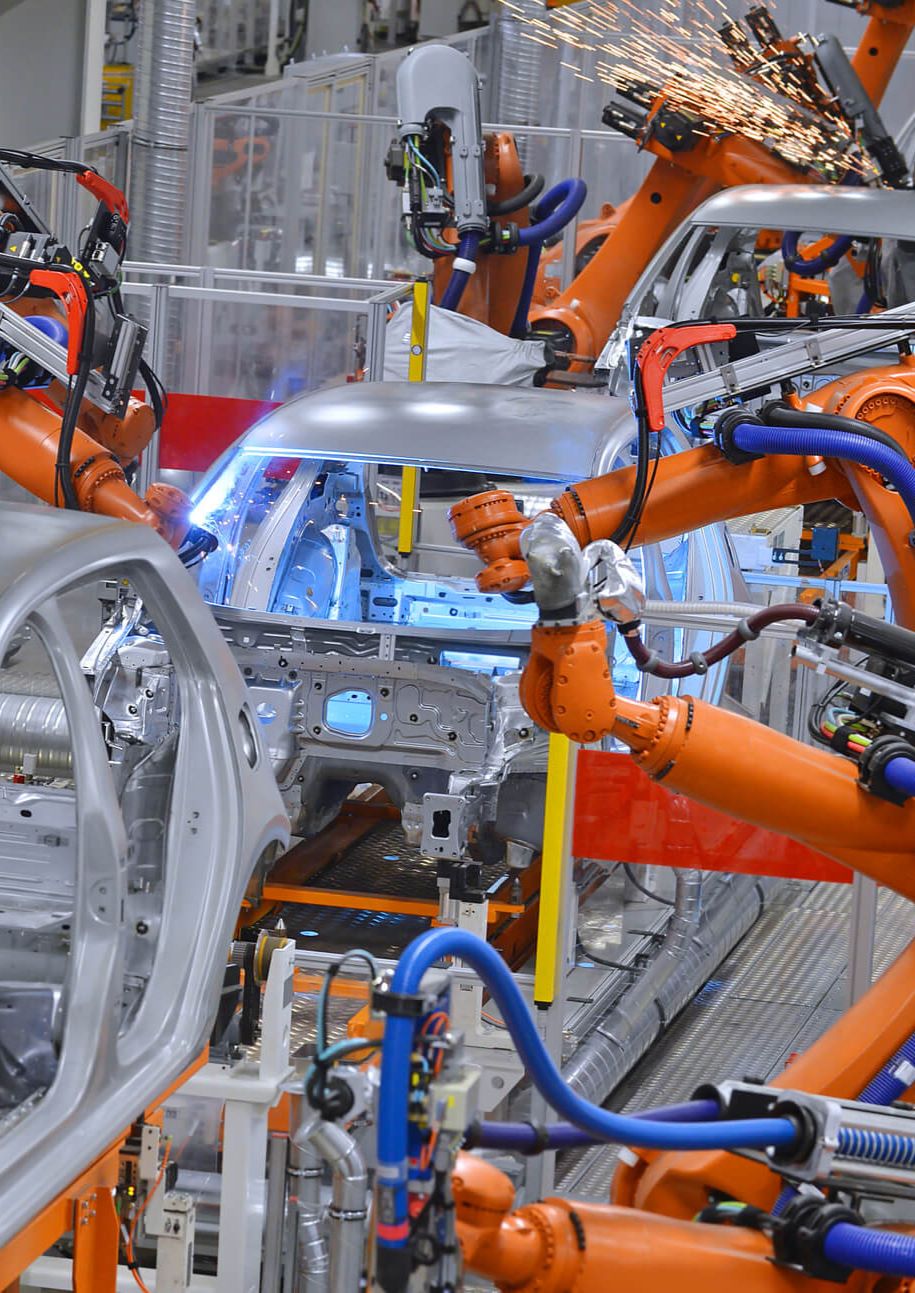

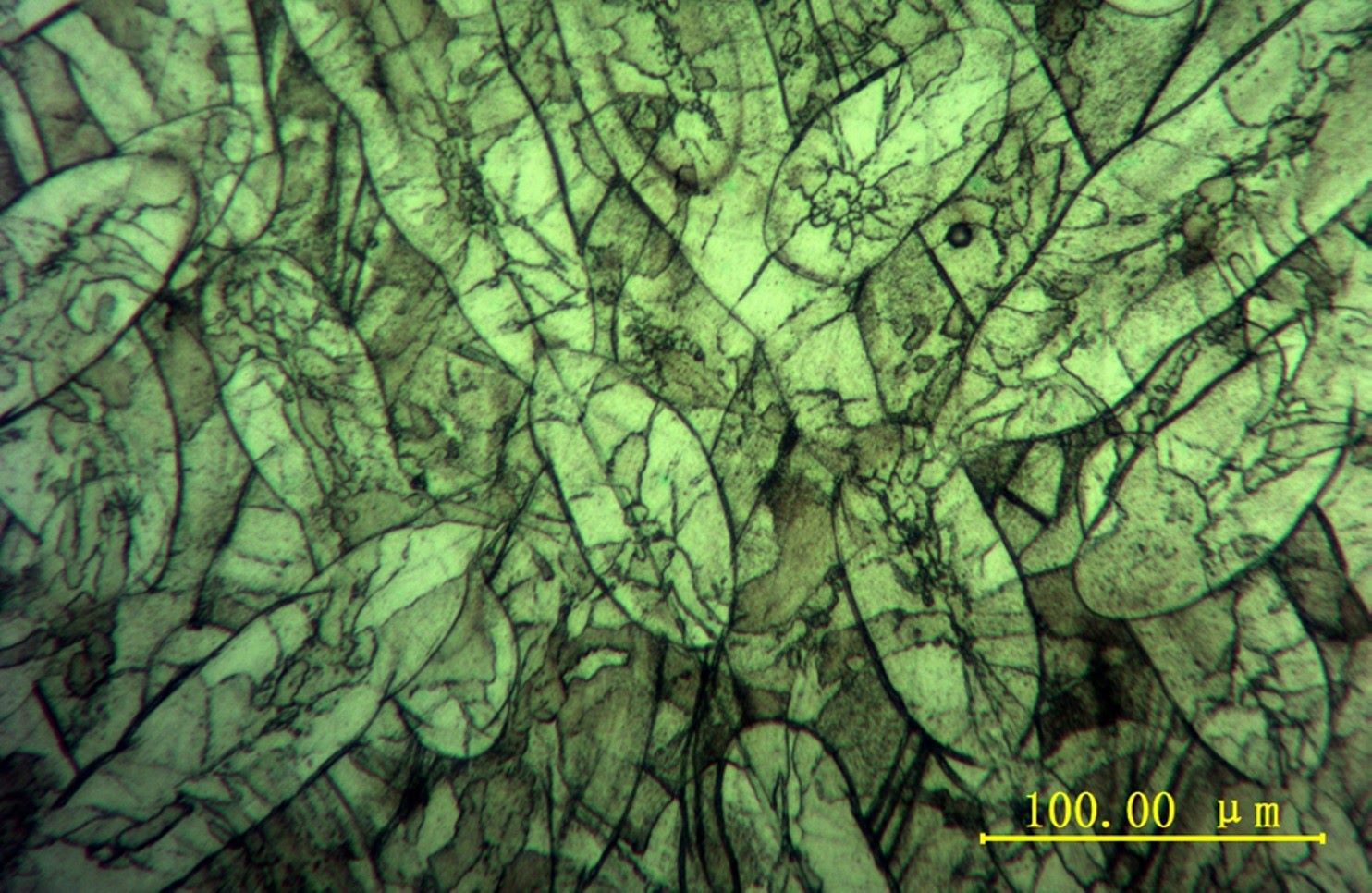

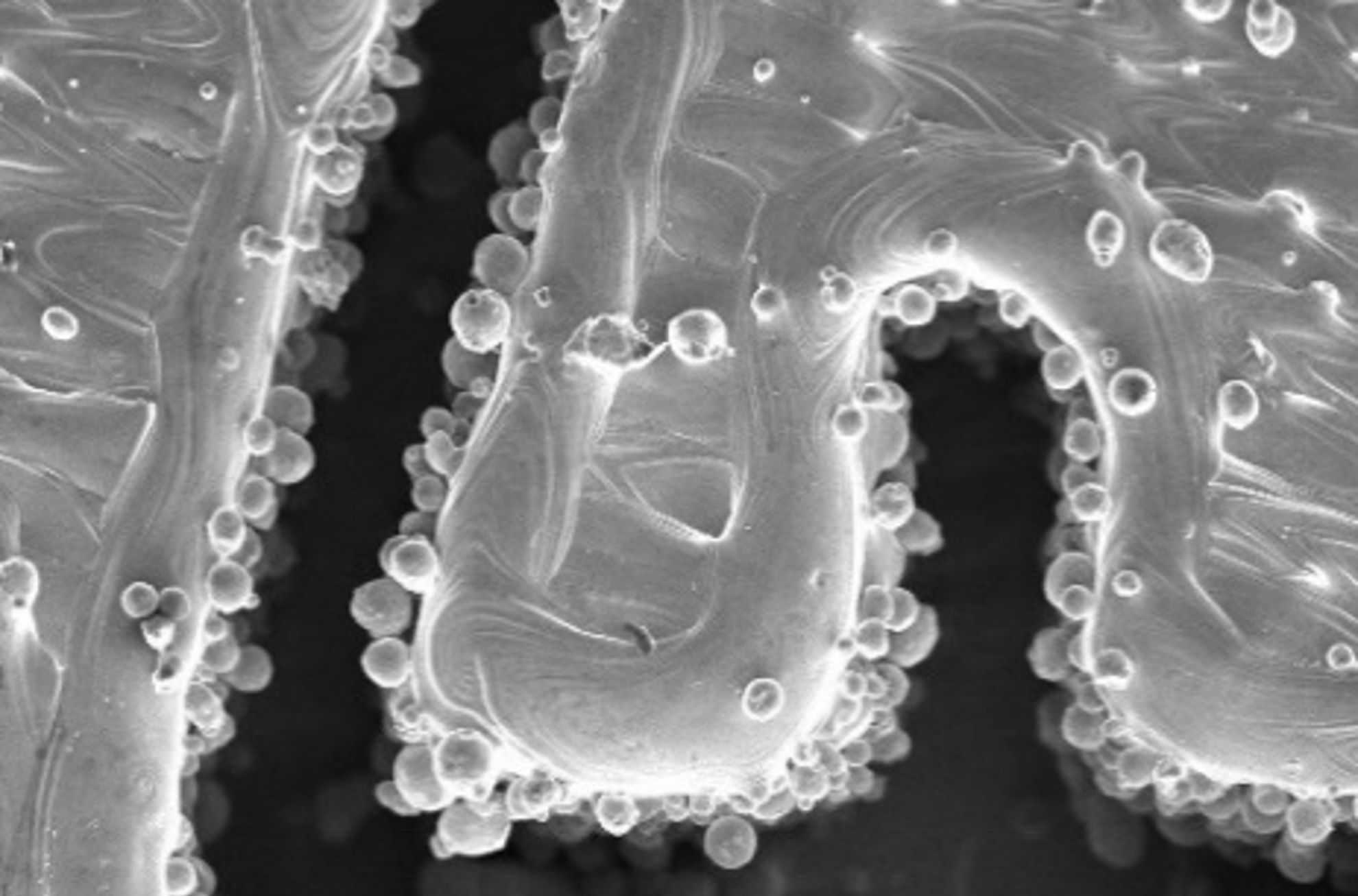

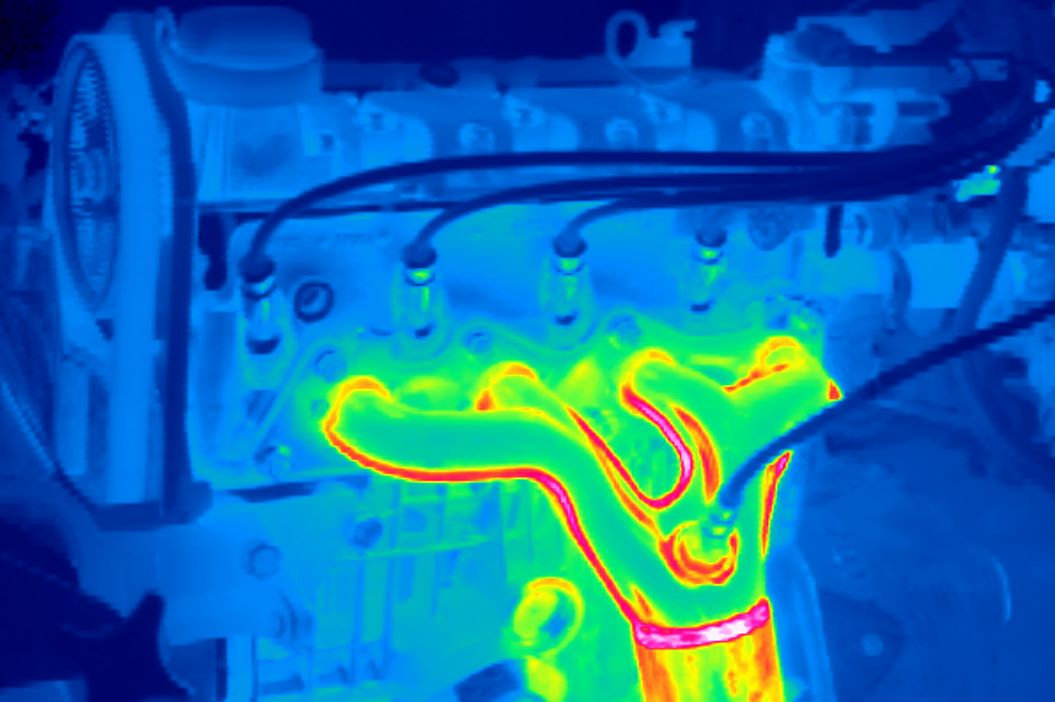

The educational activities of the research group cover all the technological processes and manufacturing systems that are found in modern vehicle manufacturing today. In the bachelor and master programmes in automotive engineering, we aim to familiarise students with the steps and the mindset required for technological design, from materials science to technological design and systems theory. In the BSc. and MSc. specialisations, we aim to provide students with design and project assignments to master all of this at a skill level. Our research activities mainly focus on applications and properties of advanced alloys, such as amorphous and nanocrystalline alloys, hydrogen storage alloys, materials science aspects of advanced technological processes, bonding technologies, laser machining, laser material processing, surface treatments, bonding technologies, cutting and additive technologies, especially laser metal printing (SLM). The main focus of the tasks is on the exploration of technological correlations and their application to process development. ). Our state-of-the-art tools also allow us to perform process diagnostics and process optimisation tasks. We collaborate with industry, both multinational and SME, in the fields of education, research and development.

Key industrial partnerships, most significant projects

Since its establishment, the research team has been involved in the following projects:

- Investigation of local hardening caused by plate formation for the Bosch Group

- Performing process diagnostics and process optimisation tasks for Ford and Continental,

- Optimisation of turning technology to achieve the best surface roughness on stainless steel parts for HNF Technologies

- Laser cutting of nanocrystalline soft magnetic alloys and thermal interaction zone testing for the production of next generation electric motors (Dynamics and control of autonomous vehicles in synergy with the requirements of automated transport systems, EFOP-3.6.2-16-2017-00016)

- Strength testing of bolted joints for Electraplan-Production Ltd.

- Development of post-gluing heat treatment technology and heat treatment equipment for current collectors for Morgan Hungary Kft.

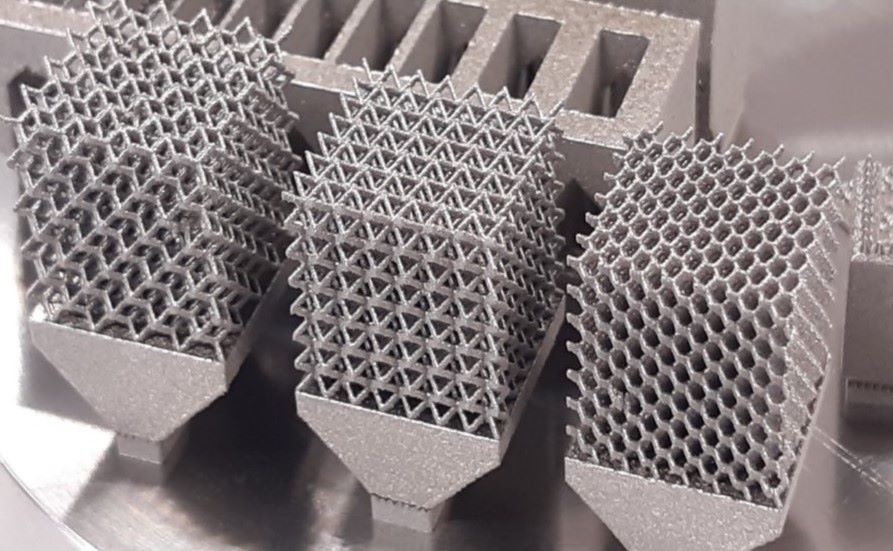

- Material properties testing of 316L and Ti6Al4V alloys produced by selective laser melting (NVKP-16, TKP, GINOP, KTNL and Mouldtech Systems)

- Efficiency-enhanced and smart manufacturing technologies (TKP):

- In the framework of the university’s excellence programme, the research group has determined the impact of 3D printing preparation operations (orientation, support, process simulation) and different metal powder materials (steel, titanium) on the printability and properties of the finished model in relation to laser beam metal powder additive manufacturing. Partner.

- Investigating the characteristics of laser surface treatment:

- Developing a new generation of manufacturing processes for customised biomedical implants and assistive devices using additive technologies. A consortium of Varinex Zrt. and BME has developed a prototype system for the production of customized implants and related devices using advanced additive manufacturing processes for metals and polymers. The sample system, developed in collaboration with BME co-investigators, ranges from X-ray and CT scans to approved printed models. The department has carried out the main research in the field of metal 3D printing. Partner.

- Creating a multi-purpose, fixed-wing drone based on innovative and novel solutions and the competences to develop it:

- In the framework of the project, the research team developed an intelligent, fixed-wing, unmanned aircraft and the associated competence. Partner: MouldTech Systems Kft.

- Key results that are also of industrial use

- The results achieved by the research team will help to enhance the competences and capabilities of our industrial partners.

Key results that are also of industrial use

- Development of heat treatment technology for the heat treatment of additively manufactured high Ni tool steels (Mouldtech Systems)

- Development of a post bonding heat treatment technology and heat treatment apparatus for current collectors (Morgan Hungary Kft.)

- Optimisation of turning technology for best surface roughness on stainless steel parts (HNF Technologies)

The research team’s relations with students

The research team is heavily involved in the teaching of the professional core curriculum of all three BSc courses at the KJK, Automotive Engineers, Transport Engineers and Logistics Engineers, and the MSc course in Automotive Engineering. In addition, we maintain the BSc and MSc Specialisations in Vehicle Manufacturing and Repair, where we train vehicle engineers specialised in the operation and design of manufacturing technologies and systems in the automotive industry. A large number of students are also involved in the research activities of the research group in the form of student research projects, theses and dissertations. In addition, PhD students are conducting their doctoral research on laser technologies, with the main focus now on laser beam powder bed additive manufacturing. The results of the research carried out by the research group are also being integrated into education.